Rebuilding Global Resilience Through Physical AI and Trusted Partnerships

This essay is part of the Made in Democracy series, exploring how allied nations can rebuild industrial and technological strength to sustain freedom in a more contested world.

______________________________________________________________________________________________________

Across capitals from Washington to Tokyo to Berlin, a quiet consensus is emerging: nations that value openness and transparency cannot secure prosperity or peace if they rely on authoritarian powers for the machinery that sustains their economies and defenses. The question is no longer whether to reshore or friend-shore, but how to reimagine manufacturing itself—through the intelligent fusion of artificial intelligence and industrial systems.

The next industrial era will be shaped by Physical AI: machines that not only think, but also see, move, and build. Harnessed responsibly, this frontier can strengthen the world’s open, rules-based economies. Ignored, it risks deepening existing imbalances in global production.

Moving Beyond the Myth of the “Manufacturing Job”

Calls to “bring back manufacturing jobs” often evoke memories of steady, lifelong work that required no post-secondary education. That vision belongs to another era. Modern production is less about labor quantity than ecosystem quality—continuously refined through digital twins, robotics, and advanced materials.

The Sharpie plant in Maryville, Tennessee, offers a glimpse of the future. Newell Brands invested nearly $2 billion to reshore production using robotics, producing half a billion markers each year at lower cost—and with no layoffs. Workers became robotics technicians, not assembly-line operators. It is the model for industrial renewal: smart automation, not job nostalgia.

The goal is not to recreate the factories of the 1950s but to rebuild the innovation networks that will power production in the 2050s. Reviving industrial capacity should not be about sentiment—it is about shared resilience and opportunity.

Closing the Industrial Gap Means Closing the Automation Gap

It is often said that you will not lose your job to a robot, but to someone using robots. The defining contest of this century will hinge on how societies integrate intelligent machines into production.

China’s demographic pressures have made automation a national imperative. Its factories installed nearly 300,000 new industrial robots last year—more than the rest of the world combined. In total, China now operates over two million robots, roughly double the installed base of the United States and its partners combined. Chinese manufacturers use 12 times more robots than U.S. manufacturers when controlling for wages. When a lower-wage nation automates significantly faster than its high-wage competitors, it risks creating a new web of choke points—across the full spectrum of goods that automation enables.

For open economies, the priority must be recapturing industrial capacity first and treating job creation as the outcome of innovation, not the driver. Doing so will enable more Sharpie-style renewals: advanced, automated facilities that restore production locally and create new, higher-skill employment.

The Physical AI Opportunity

The surest way to strengthen global competitiveness is for trusted partners to align industrial strategies, share risk, and build scale collectively.

Each participant brings unique strengths: Japan, Germany, and Korea in hardware precision and robotics; the United States in software and AI. Fusing these capabilities can forge a new manufacturing paradigm—one in which open, cooperative economies lead in Physical AI and the advanced factories that flow from it.

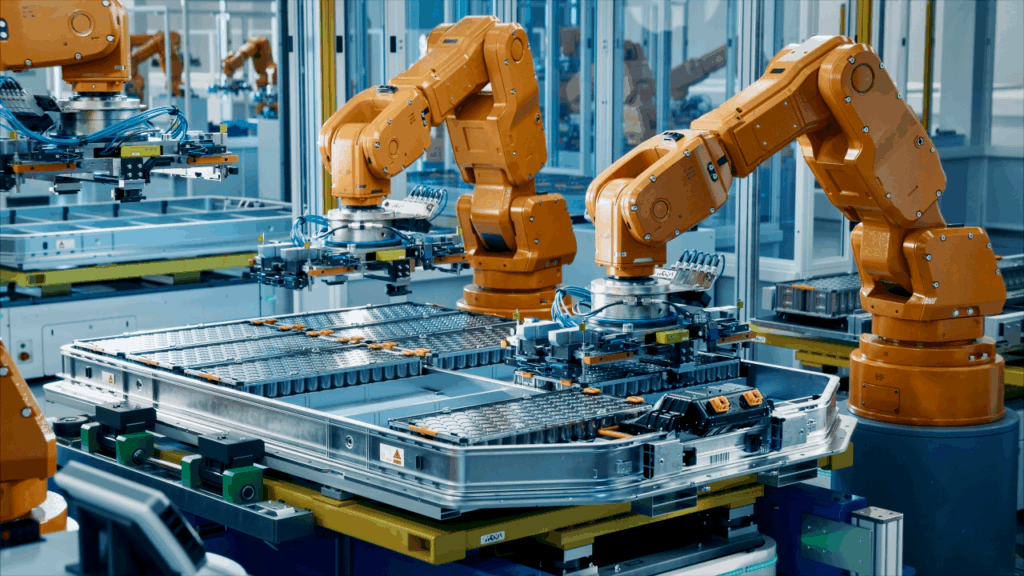

From Foxconn’s lights-out smartphone plants in Shenzhen and Midea’s AI-driven appliance factories in Jingzhou to Tesla’s Gigafactories in Austin and Berlin and Siemens’ self-learning electronics works in Amberg, the frontier of industrial automation is no longer theoretical—it is operational and expanding. These facilities show that Physical AI—the fusion of robotics, data, and design—is already transforming how the world builds everything from rockets to refrigerators. The challenge now is clear: open, rules-based partners must accelerate this transformation together—scaling intelligent manufacturing not only to compete, but to ensure that the next generation of production power rests on systems that are secure, trusted, and shared.

From Tariffs to Trust

Trade policies that inadvertently penalize reliable partners weaken the very supply chains they aim to secure. A more effective approach is to build a trusted manufacturing network—a framework where transparent sourcing, shared standards, and reciprocal access bind production across like-minded economies.

High posted tariff rates can still serve a strategic purpose when paired with preferential treatment for trusted sourcing in sectors vital to collective resilience—semiconductors, pharmaceuticals, and critical minerals. The goal should not be protectionism, but partnership-based openness: encouraging cooperation among reliable producers while reducing vulnerability to distortion or coercion.

Building a Club for Good™

This manufacturing renewal could evolve into a Club for Good—a coalition of open, rules-based economies whose products, data systems, and supply chains are mutually recognized as secure and transparent.

As outlined in Interoperability as a Club Good: An Idea Worth Exploring, this model balances openness within trusted circles with appropriate safeguards against exploitation.

Initially conceived for digital cooperation—chips, algorithms, and cloud systems—the same logic applies to the physical infrastructures that produce them.

Membership would be earned, not assumed. Participants aligning on cybersecurity, export-control practices, and transparent supply-chain data would gain preferential access to shared markets and technologies. Over time, “most-favored nation” could yield to a new principle: most-trusted partner.

The Strategic Imperative

Industrial capacity is the foundation of credible diplomacy, sustainable development, and collective security. Physical AI provides the lever; trusted-network manufacturing the fulcrum; international cooperation the scale.

Together, open and rules-based partners can restore balance to global production, enhance energy and digital resilience, and ensure that the technologies shaping tomorrow’s world serve the broader human good.

Reimagining manufacturing through Physical AI is not nostalgia—it is strategy.

It is how innovative societies can renew confidence in global collaboration, expand shared prosperity, and prove that ingenuity and openness remain the most powerful combination on earth.

In line with my belief that responsibly embracing AI is essential to both personal and national success, this piece was developed with the support of AI tools, though all arguments and conclusions are my own.

Author

Mark Kennedy

Director & Senior Fellow